The bayonet heater is customized by our factory according to the requirements of modern industrial electric furnace (small size and high power), which has the characteristics of high resistivity, small temperature coefficient of resistance and high operating temperature. It has good corrosion resistance at high temperature and is especially suitable for use in atmospheres containing sulfur and sulfide. It is an ideal heating material in industrial electric furnaces, household appliances and far-infrared devices. The bayonet heaters currently produced by our factory:

1. The heating element adopts ultra-high temperature resistance alloy, which has good resistance to high temperature oxidation and resistance stability, and has a longer service life;

2. High-aluminum ceramic skeleton is used, which has good high temperature strength and electrical insulation performance;

3. The single power is powerful, and the installation and maintenance are convenient;

4. Reasonable thermal insulation structure design can effectively prevent heat loss and save more energy.

In the production process, our factory strictly controls the following steps:

(1) Electric heating material

It is required that the heating wire has a high degree of heat resistance; the material has no impurities, no segregation, and strong chemical ability; in the process of use, there is no deformation, no breakdown, and no loopholes.

(2) Refractory material

The refractory material is required to be corundum. During the working process of the radiant tube, it has high high temperature strength and high temperature insulation ability, and does not break or leak.

(3) The protective cover is closed

When the OCr25Ni20Si2 cover used by our factory is locally heated, the deformation of the tube body is very small, which has no effect on the heating element and the working environment in the furnace; the heat resistance is strong, and the normal use time is 6000~10000 hours, which is the domestic level.

(4) Production process

During the straightening process of the heating wire, there is no crack; during the welding process, the welding meat is full and flat, and there is no overheating segregation and virtual welding.

After a large number of customers use it, it is confirmed that under normal working temperature and load, the electric heating radiant tubes produced by our factory can be used for more than 8000 hours in various furnace bodies. The factory welcomes people from all walks of life to visit and guide, and is willing to discuss with colleagues in the industry and make progress together.

Product use and maintenance

1. Use

(1) Prohibit long-term over-temperature and overload use;

(2) When the furnace temperature is as high as 400°C, rapid cooling is not allowed;

(3) Do not touch the resistance belt when loading and discharging;

(4) When the furnace is working, always pay attention to whether the traffic lights on the control panel are normal. When keeping warm, the traffic lights should be exchanged once after a period of Copper heater OEM Factory time, so as to avoid burning the electric furnace wire due to the failure of the control switch;

(5) Pay attention to the working conditions of the instrument at any time, and analyze and deal with it in time when the furnace temperature and the indication of the instrument are found to be abnormal;

(6) For furnaces with a capacity of more than 100KW, each heating zone should be equipped with an ammeter for inspection, and an ammeter should be installed in each phase of the sedan high-temperature electric furnace.

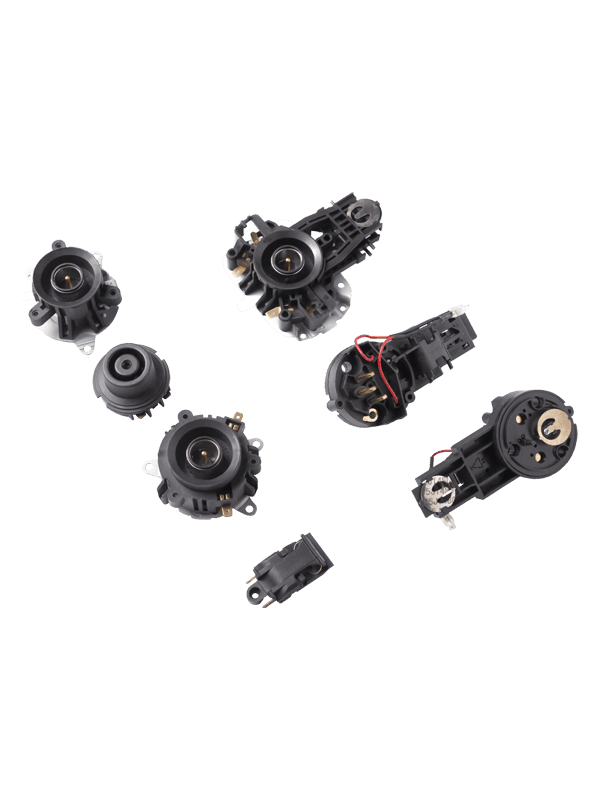

Kettle Thermostat Couplers

| Name: |

Couple/Kettle Thermostat |

| Material: |

Plastic and Stainless steel,copper |

| Processes |

Wave soldering machine,shell injection molding machine,SMT placement machine,(wave soldering-aging test-Semi-finished product test-plastic mold forming ) |

| Describe |

Good material, small dimensional tolerance, good performance (suitability), and good surface quality. |

| QC |

|

English

English